PVC co-extruded board

PVC cabinets are a popular choice for kitchens, bathrooms, and other storage areas due to their durability, affordability, and low maintenance.

Keywords:

PVC CO-EXTRUSION FOAM BOARD

Category:

PVC CO-EXTRUSION FOAM BOARD

PVC co-extruded board

Product Parameters

| Percentage | <0.4% | Tensile Strength | 12-20MPa |

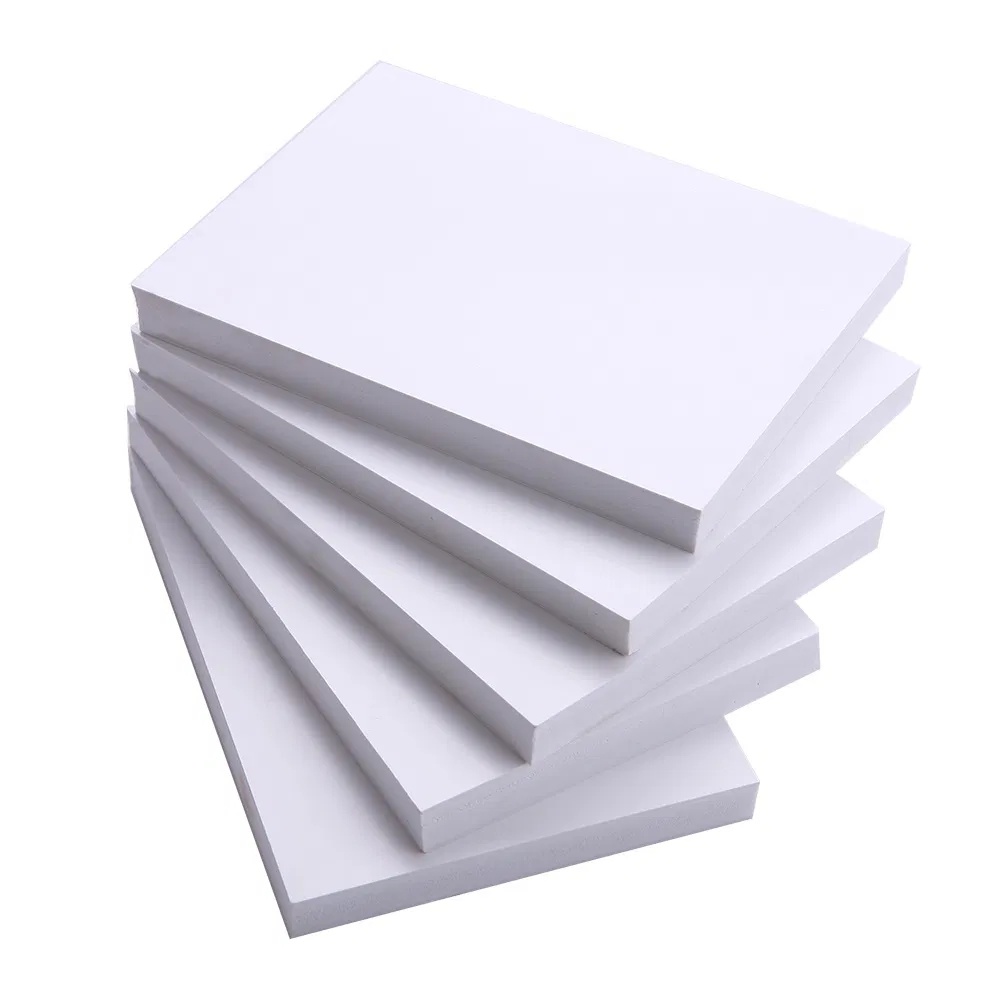

| Color | White, Black, Green, More Than 100 Kinds of Color | Density | Minimum 0.4g/cm3 |

| Attributes | Eco-Friendly, Fireproof, Waterproof, Easy to Pprocess, High Toughness | Thickness | 3mm |

| Foam Process | Celuca, Extrude, Hardness Surface | Size | 1220X2400mm,1560*3050mm,2050*3050mm and Coustomizable |

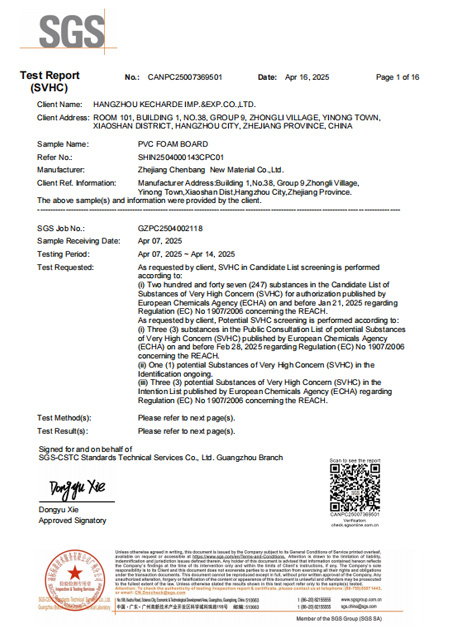

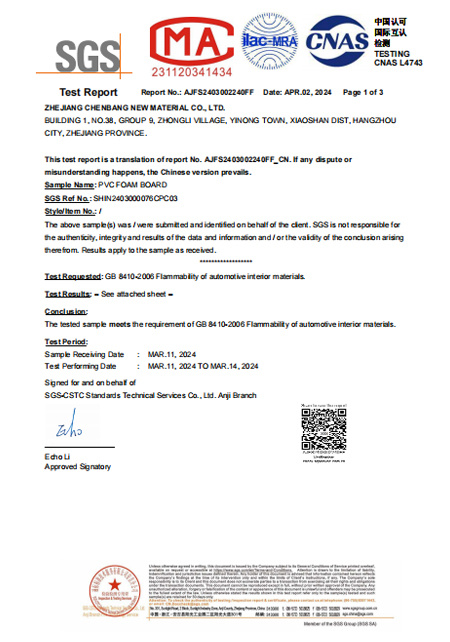

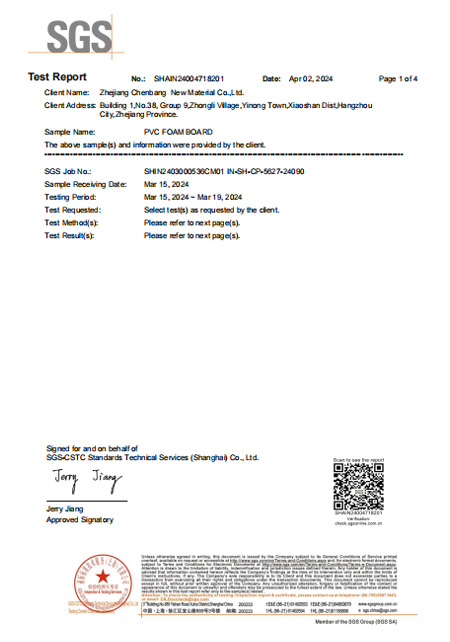

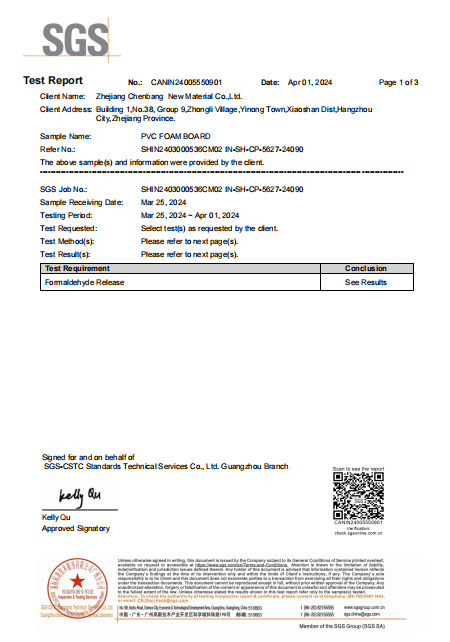

| Flame Retardence | Self-Extinguishing Less Than 5 Seconds | Certification | SGS CE ISO9001 |

| Processing Effect | The Edge Smooth After Cut by CNC | Application | Advertising, printing, furniture, cabinets, decora |

| Transport Package | Plastic Bags, Pallets, Cartons, Kraft Papers | Processing | can be drilled, cut, nailed, engraved |

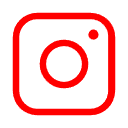

WORKSHOP

PRODUCT FEATURES

①Cost Efficiency

·Lower cost compared to other boards, ideal for budget - conscious projects.

②Uniformity and Stability

·Resists warping or twisting due to temperature and humidity changes.

·Flat surface ideal for various finishing treatments.

③Environmental Friendliness

·Meets stringent E0 formaldehyde emission standards (≤ 0.050 mg/m³) for environmental

④Versatility

·Various of Usages: Suitable for furniture manufacturing (such as cabinets, toilet partition and etc.), interior decoration (making interior wall panels to provide a flat surface for subsequent decoration), advertising area (UV printing,advertising design,display racks) etc.

·Easy to cut, drill, and assemble for mass production and customization.

⑤Lightweight

·Lighter than wood or other boards, reducing handling and installation difficulty.

CERTIFICATION

Next

Related products